In today’s fast-paced industrial world, precision, reliability, and efficiency are critical to success. From aerospace and automotive to medical devices and electronics, manufacturers across industries demand components that meet the highest standards of accuracy and durability. Enter Swiss machined components—a pinnacle of machining technology renowned for their unrivaled precision and quality. With the integration of advanced CNC machining, Swiss machined parts have become the gold standard for industries that cannot compromise on performance.

But what exactly makes Swiss machined components so advantageous for industrial applications? Let’s explore the technology, process, and unique benefits that set Swiss machining apart from traditional CNC machined components, and why so many manufacturers trust these parts for their most demanding needs.

Understanding Swiss Machining

Swiss machining, also known as Swiss-type or Swiss screw machining, refers to a highly specialized process originally developed in Switzerland for producing precision watch parts. Unlike conventional lathes, a Swiss CNC machine holds the workpiece with a sliding headstock and guides it through a stationary guide bushing, allowing for unparalleled control, support, and accuracy—especially with long, slender, or complex components.

Modern Swiss CNC machines combine this unique architecture with computer numerical control (CNC) capabilities, enabling the production of intricate geometries and tight tolerances across large production runs. Today, Swiss machining is synonymous with excellence in manufacturing CNC machined parts that are small, intricate, and essential to high-performance products.

1. Unmatched Precision and Tolerances

The hallmark of Swiss machined components is their extraordinary precision. The guide bushing supports the workpiece right next to the cutting tool, minimizing deflection and vibration. This means even extremely thin or long parts can be machined with tolerances as tight as ±0.001 mm (±0.00004 inches).

For industries such as medical device manufacturing, aerospace, and high-end electronics, where every micron matters, this level of precision is crucial. Swiss CNC machined parts consistently meet the stringent specifications required for critical applications like surgical tools, fluid connectors, or electronic sensors.

Key benefit:

- Repeatable, ultra-tight tolerances for mission-critical applications.

2. Superior Surface Finishes

A smooth, high-quality surface finish is essential for parts that interface with other components, move within assemblies, or must meet hygiene or aesthetic standards. Swiss machining excels in this regard. The close proximity of the cutting tool to the supported workpiece eliminates chatter and delivers superior surface finishes—often minimizing or eliminating the need for secondary finishing operations.

In the medical industry, for example, Swiss machined components used in implants or instruments require impeccable finishes to ensure safety and patient comfort. In electronics, smoother surfaces mean better performance and fewer connectivity issues.

Key benefit:

- High-quality finishes that reduce the need for additional processing and improve overall component performance.

3. Complex Geometries and Small Part Production

Traditional machining processes can struggle with small, intricate, or highly detailed parts. Swiss CNC machining, however, is specifically engineered for such challenges. With multi-axis capabilities (often up to 12 axes or more), Swiss-type machines can perform milling, drilling, turning, knurling, and threading operations in a single setup.

This flexibility makes Swiss machining ideal for producing components with:

- Micro-sized features or tight radii

- Multiple cross holes or slots

- Threads and tapers

- Complex profiles that would require multiple processes with standard lathes

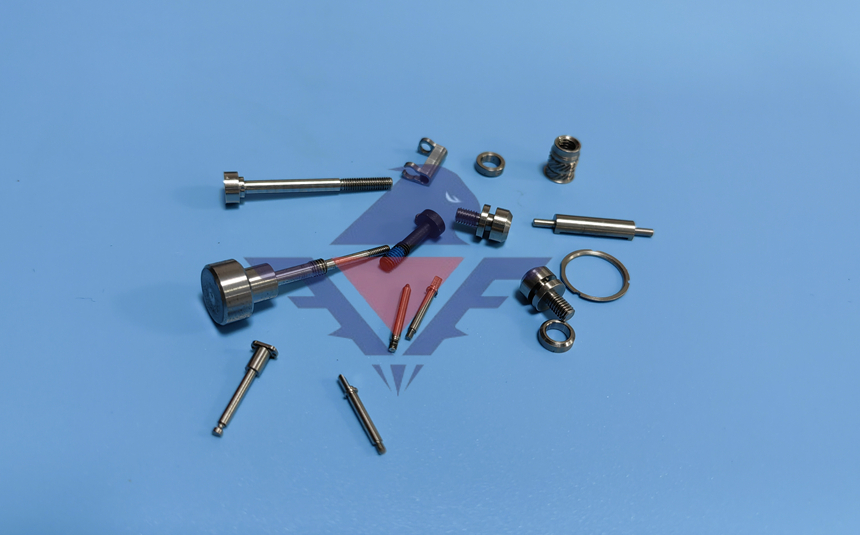

As a result, industries like electronics, dental, and aviation rely on Swiss machined parts for connectors, fasteners, pins, bushings, and specialty fittings.

Key benefit:

- Ability to manufacture highly complex, miniature, or detailed CNC machined components in one efficient process.

4. Increased Efficiency and Throughput

Efficiency is a defining feature of Swiss CNC machining. Because many operations can be performed simultaneously (thanks to multiple tools and axes), cycle times are significantly reduced. Swiss machines often feature automatic bar feeders, enabling lights-out manufacturing and high-volume production without constant operator intervention.

This translates to:

- Faster turnaround times for large orders

- Consistent, repeatable quality from the first part to the last

- Lower labor costs and reduced risk of human error

For manufacturers facing tight deadlines or requiring rapid scalability, Swiss machining offers a clear advantage over standard CNC machined parts.

Key benefit:

- Rapid, high-volume production with consistent quality and reduced manual oversight.

5. Reduced Material Waste and Cost Savings

Swiss machining’s accuracy isn’t just about quality—it’s also about economy. The close guide bushing allows for aggressive cuts with minimal material deflection, reducing scrap rates even with challenging materials or thin-walled parts. Multi-operation capability in a single setup also reduces setup time and material handling, leading to further savings.

For industries using expensive materials like titanium, stainless steel, or specialty alloys, minimizing waste means significant cost reductions per part. These savings, combined with high throughput and reliability, make Swiss machined components an economical choice for both prototyping and mass production.

Key benefit:

- Cost-effective manufacturing with minimal material waste—especially important for high-value materials.

6. Versatility Across Materials

Swiss CNC machining is compatible with an impressive range of materials, from soft plastics to the hardest superalloys. Common materials include:

- Stainless steel, titanium, and medical-grade alloys

- Aluminum, brass, copper, and bronze

- Engineering plastics (PEEK, Delrin, PTFE)

- Exotic alloys for aerospace or automotive use

This versatility allows manufacturers to select the best material for their application, knowing Swiss machines can handle even the most demanding specifications.

Key benefit:

- Flexibility to produce CNC machined parts from almost any machinable material.

7. Consistent Quality for Regulated Industries

Industries such as aerospace, defense, and medical devices face strict regulatory requirements. Traceability, process control, and documentation are essential. Swiss CNC machining, with its automation and repeatability, ensures that every component meets rigorous quality standards.

Many Swiss machining suppliers are ISO 9001, AS9100, or ISO 13485 certified, further validating their commitment to quality. CNC machined parts produced via Swiss machining are trusted in life-critical and safety-sensitive environments.

Key benefit:

- Reliable, certifiable quality assurance for applications where failure is not an option.

8. Customization and Prototyping

While Swiss machining is famed for large production runs, it’s also ideal for prototyping and low-volume, custom work. CNC technology makes it easy to adjust designs, dimensions, and features between runs. Engineers can rapidly iterate on prototypes, test different materials, and transition seamlessly from small batches to full-scale manufacturing.

Key benefit:

- Agile response to changing designs and rapid prototyping without sacrificing precision.

9. Environmental Benefits

Reduced waste, energy-efficient machines, and the ability to use recyclable materials make Swiss CNC machining an environmentally friendly option. Manufacturers can achieve sustainability goals without compromising on part performance or reliability.

Key benefit:

- Supports greener manufacturing processes through efficiency and material conservation.

Conclusion: The Swiss Advantage in Industrial Applications

In summary, Swiss machined components represent the cutting edge of CNC machined parts for industrial applications. Their advantages—precision, complex geometry capability, superior finishes, efficiency, cost-effectiveness, and adaptability—make them indispensable in fields where quality is non-negotiable.

Whether producing millions of micro-electronic connectors or a handful of custom medical implants, industries around the world trust Swiss CNC machining to deliver results. As manufacturing technology evolves, Swiss machined components continue to set the standard for what’s possible—empowering innovation, reliability, and success in every sector.

If your next project demands the best in CNC machined components, consider partnering with a trusted Swiss machining specialist. Discover how these advanced parts can elevate your products, streamline your production, and position your business for long-term growth.